2016 Fall Reports of the Commissioner of the Environment and Sustainable Development Report 1—Inspection of Nuclear Power Plants—Canadian Nuclear Safety Commission

2016 Fall Reports of the Commissioner of the Environment and Sustainable Development Report 1—Inspection of Nuclear Power Plants—Canadian Nuclear Safety Commission

Table of Contents

- Introduction

- Findings, Recommendations, and Responses

- Conclusion

- About the Audit

- List of Recommendations

- Exhibits:

- 1.1—Four nuclear power plants are operating in Canada

- 1.2—The Canadian Nuclear Safety Commission’s typical site inspection process

- 1.3—How the nuclear power plant site inspection planning process works

- 1.4—Some site inspections were not completed as planned

- 1.5—There are two types of nuclear power plant inspections

Introduction

Background

1.1 The Canadian Nuclear Safety Commission (CNSC) regulates the use of nuclear energy and materials under the Nuclear Safety and Control Act (1997) so that the environment and the health, safety, and security of Canadians are protected, and Canada’s international commitments on the peaceful use of nuclear energy are implemented.

1.2 Nuclear power plants in Canada have been producing electricity commercially since the 1960s. Based on our calculations using Statistics Canada data, in 2015, about 17 percent of Canada’s electricity, including almost 66 percent of Ontario’s electricity, came from nuclear power. Today, four nuclear power plants using 19 reactors produce electricity: three in Ontario and one in New Brunswick (Exhibit 1.1). The CNSC authorizes their operation by issuing licences that set out the conditions designed to meet the requirements of the Act and its regulations. For example, one licence condition is that nuclear power plants must maintain a radiation protection program. Licensees are responsible for ensuring the safe operation of nuclear power plants.

Exhibit 1.1—Four nuclear power plants are operating in Canada

Source: Based on information provided by the Canadian Nuclear Safety Commission

Exhibit 1.1—text version

A map shows the locations of the four nuclear power plants that are operating in Canada: three in Ontario and one in New Brunswick. A table embedded in the map shows the number of reactors at each location.

The nuclear power plant locations and reactor numbers are as follows:

- Bruce, Ontario, on the east shore of Lake Huron (8 reactors);

- Darlington, Ontario, on the north shore of Lake Ontario (4 reactors);

- Pickering, Ontario, on the north shore of Lake Ontario (6 reactors); and

- Point Lepreau, New Brunswick, on the shores of the Bay of Fundy (1 reactor).

1.3 The CNSC regulates the development, production, and use of nuclear energy by

- setting regulatory requirements,

- issuing licences with the conditions needed at each nuclear power plant,

- issuing handbooks to each nuclear power plant that set out compliance verification criteria on how to ensure that plants comply with the licence conditions, and

- verifying and enforcing compliance.

1.4 The CNSC organizes the licence conditions by technical areas, called safety and control areas, such as emergency preparedness, environmental protection, and site security. These are used by the CNSC to assess, review, verify, and report on regulatory requirements and performance across all nuclear power plants. The CNSC publishes an annual report that rates the performance of the nuclear power plants in each of the safety and control areas. The results of its site inspections serve as a key input of this annual assessment.

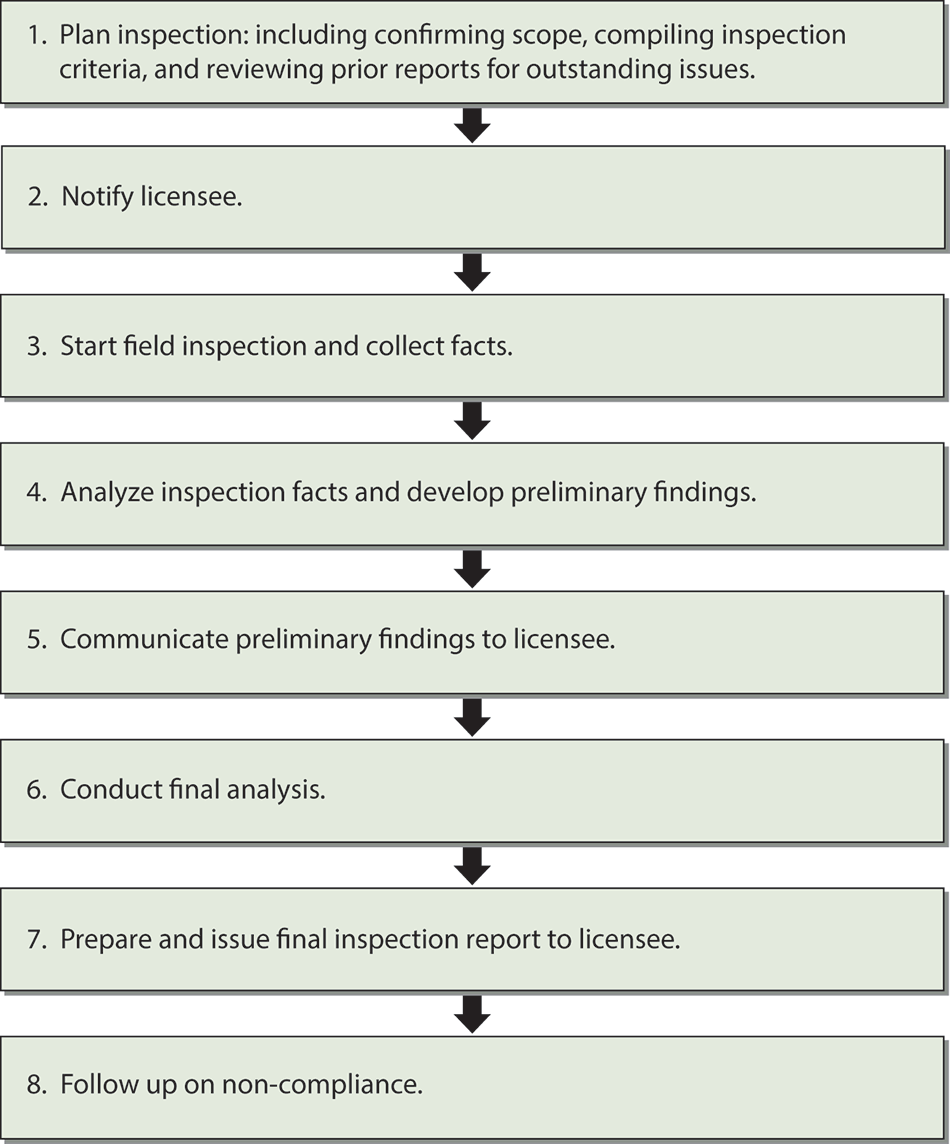

1.5 Compliance verification and enforcement are core processes within the broader oversight regime. Site inspections serve as one of the key tools that the CNSC uses to verify that plants are complying with regulatory and licence requirements. Each year, the CNSC conducts a number of inspections at each nuclear power plant, which culminate in inspection reports to the licensees (Exhibit 1.2).

Exhibit 1.2—The Canadian Nuclear Safety Commission’s typical site inspection process

Source: Based on information provided by the Canadian Nuclear Safety Commission

Exhibit 1.2—text version

This flow chart shows the Canadian Nuclear Safety Commission’s typical site inspection process. The eight steps of the process are as follows:

- Plan inspection: including confirming scope, compiling inspection criteria, and reviewing prior reports for outstanding issues.

- Notify licensee.

- Start field inspection and collect facts.

- Analyze inspection facts and develop preliminary findings.

- Communicate preliminary findings to licensee.

- Conduct final analysis.

- Prepare and issue final inspection report to licensee.

- Follow up on non-compliance.

1.6 The CNSC also undertakes a number of other activities to verify compliance. For example, the CNSC reviews documents that it requires licensees to submit, such as routine performance data and unusual occurrences. This information may identify matters that inspections need to examine. The CNSC’s staff located on site at nuclear power plants are expected to carry out daily and continuous surveillance and monitoring activities. These include attending licensee meetings, reviewing operations log books, and observing nuclear power plant operations.

1.7 Following a site inspection, the CNSC is to tell the licensee about any compliance violations the licensee needs to correct and issue a final inspection report. The CNSC is to follow up with licensees to ensure that they take appropriate corrective action. The CNSC has a number of enforcement measures at its disposal to encourage and compel compliance and deter future non-compliance.

1.8 The Office of the Auditor General conducted two previous audits of the CNSC’s oversight of the nuclear sector. In the first audit, the 2000 December Report of the Auditor General, Chapter 27—Power Reactor Regulation, we noted that the CNSC needed to improve its regulatory regime for nuclear power plants to ensure that it continued to protect the health and safety of Canadians. The divisions that regulated nuclear power reactors had used an intuitive approach, relying on the judgment and expertise of staff. As a result, the CNSC could not demonstrate whether it was doing enough or too much work in any area and whether it was overstaffed or understaffed. The report also said that the CNSC’s regulatory activities were not based on a rigorous, well-documented system of risk analysis; the ratings it assigned for regulatory performance were unclear; and the compliance and enforcement system was not complete. As a result, the CNSC could not adequately demonstrate that it was achieving its safety objectives for the regulation of nuclear power reactors.

1.9 In the second audit, the 2005 February Status Report of the Auditor General, Chapter 6—Power Reactor Regulation, we reported that overall, the CNSC had made satisfactory progress in response to the recommendations from the December 2000 audit. However, the report noted that progress had been slower than planned in developing a formal, well-articulated, systematic risk-management approach to the regulation of nuclear power reactors.

Focus of the audit

1.10 This audit focused on whether the Canadian Nuclear Safety Commission had adequately managed its site inspections of Canadian nuclear power plants to verify that the environment and the health, safety, and security of Canadians were protected. More specifically, we examined whether the CNSC adequately planned for and carried out site inspections of nuclear power plants. We also examined whether the CNSC applied enforcement measures to ensure that the deficiencies it identified were corrected to comply with regulatory and licence requirements. The audit focused on the management by the CNSC of its site inspections, and not on the overall safety of nuclear power plants in Canada.

1.11 This audit is important because inspections are one of the key tools the CNSC uses to verify that nuclear power plant operators are complying with regulatory and licence requirements and managing nuclear power plants in a way that protects the environment and the health, safety, and security of Canadians. Inspections are carried out to identify and document safety and control issues, communicate them to operators, and follow up to ensure they are corrected.

1.12 More details about the audit objective, scope, approach, and criteria are in About the Audit at the end of this report.

Findings, Recommendations, and Responses

Planning inspections

The Canadian Nuclear Safety Commission could not show that it had an adequate, systematic, risk-informed process for planning site inspections at nuclear power plants

1.13 Overall, we found that the Canadian Nuclear Safety Commission (CNSC) had insufficient or incomplete documentation to support or explain its planning decisions. For example, it could not show how it had taken risks into account when making decisions about which inspections it would and would not carry out each year. The CNSC could not show that it had determined the minimum number and types of inspections needed to verify that nuclear power plant operators were complying with regulatory and licensing requirements. We recognize that the CNSC’s planning process must be flexible enough to respond to unforeseen events or issues. However, that does not preclude the need for a systematic, well-documented process so that the CNSC can demonstrate that its planning considers risk and that it allocates enough staff at the levels needed, commensurate with risk.

1.14 These findings are important because the CNSC needs to show that it carried out the appropriate number and types of site inspections. Site inspections are one of the key verification tools the CNSC uses to assure Canadians that nuclear power plants perform safely and comply with regulatory and licence requirements.

1.15 Our analysis supporting this finding presents what we examined and discusses

- the CNSC’s ability to carry out its baseline five-year site inspection plans,

- the preparation of annual site inspection plans,

- the CNSC’s ability to carry out its annual site inspection plans,

- the determination of staffing requirements, and

- criteria for initiating program-based inspections.

1.16 The CNSC determines the number, type, and frequency of site inspections it needs to conduct to verify that licensees are operating according to regulatory and licensing requirements. In addition to planned inspections of nuclear power plants, the CNSC also conducts inspections as issues arise.

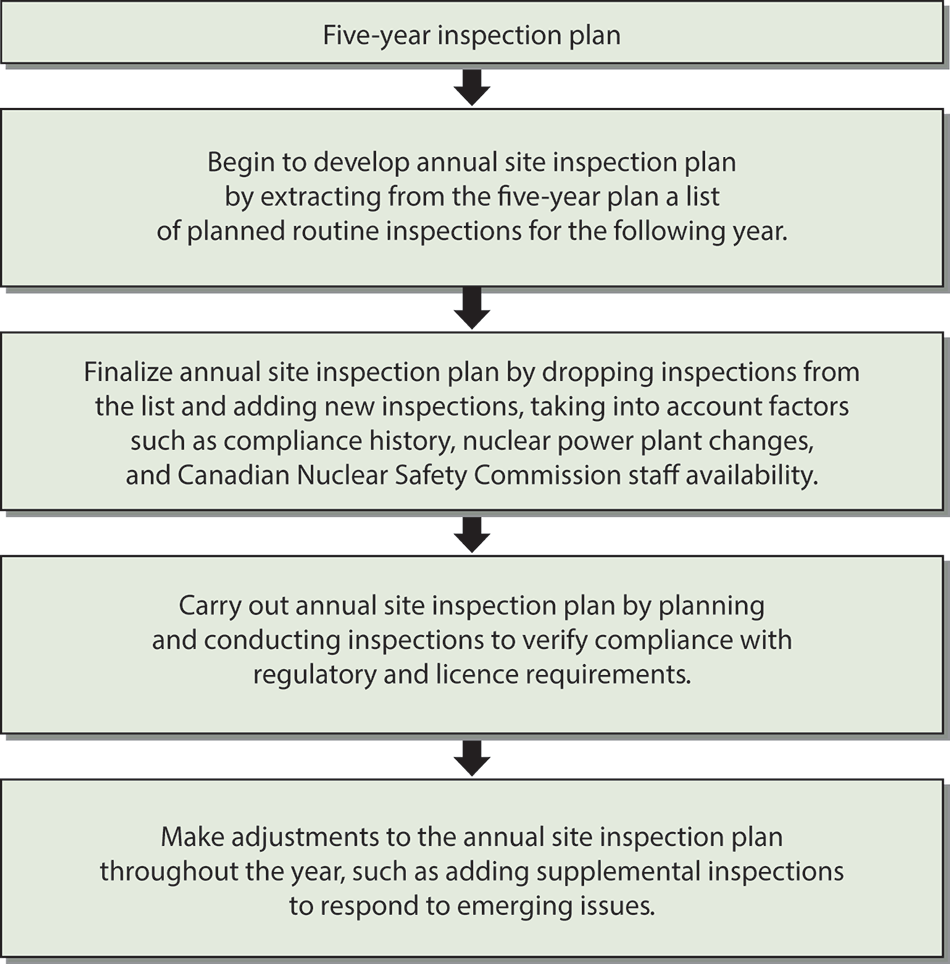

1.17 The CNSC decides what site inspections it will carry out for each upcoming fiscal year through an annual planning process (Exhibit 1.3). This process begins with extracting a list of site inspections scheduled for the upcoming year from a five-year plan. The five-year plan in effect during the period of our audit covered the 2012–13 to 2016–17 fiscal years. The CNSC then holds a series of internal consultations and makes adjustments to this list to develop annual site inspection plans. The annual site inspection plans set out the number and type of site inspections the CNSC plans to carry out during the upcoming fiscal year at each nuclear power plant. During any given year, the CNSC may cancel or postpone planned site inspections, and may conduct supplemental site inspections.

Exhibit 1.3—How the nuclear power plant site inspection planning process works

Source: Based on information provided by the Canadian Nuclear Safety Commission

Exhibit 1.3—text version

This flow chart shows how the planning process for nuclear power plant site inspections works. The process is as follows:

- Start with the five-year inspection plan.

- Begin to develop an annual site inspection plan by extracting from the five-year plan a list of planned routine inspections for the following year.

- Finalize the annual site inspection plan by dropping inspections from the list and adding new inspections, taking into account factors such as compliance history, nuclear power plant changes, and Canadian Nuclear Safety Commission staff availability.

- Carry out the annual site inspection plan by planning and conducting inspections to verify compliance with regulatory and licence requirements.

- Make adjustments to the annual site inspection plan throughout the year, such as adding supplemental inspections to respond to emerging issues.

1.18 In its 2015–16 Report on Plans and Priorities, the CNSC reported that its program responsible for regulating nuclear power plants consisted of about 200 full-time-equivalent employees. The CNSC has inspectors stationed at the nuclear power plants who, in addition to other oversight duties, are responsible for carrying out site inspections. As of May 2016, the CNSC had 24 inspectors at the plants. Technical specialists based out of the CNSC’s headquarters in Ottawa also provide support in planning and conducting site inspections. For example, a technical specialist may be called upon to review complex calculations or provide assistance in areas where the site office does not have adequate experience.

1.19 Our recommendations in this area of examination appear at paragraphs 1.33 and 1.35.

1.20 What we examined. We examined the process used by the CNSC to plan its site inspections of nuclear power plants and whether it was able to carry out its plans. We also examined whether the CNSC could demonstrate that it had planned for enough staff to carry out the necessary site inspections.

1.21 The CNSC’s ability to carry out its baseline five-year site inspection plans. According to the CNSC’s documents, it developed a five-year routine site inspection plan to set out the minimum number of inspections that should be completed during a five-year period. The plan’s purpose was to ensure that nuclear power plants complied with regulatory and licence requirements. For example, an inspection of the effluent control and monitoring program of each nuclear power plant is to be conducted about twice in five years. Among other things, this would verify whether the nuclear power plant regularly calibrates its monitoring equipment. However, CNSC officials told us that the five-year plan had been changed to a plan covering all possible site inspections. We found that, as a result, the CNSC had not systematically determined the minimum number of site inspections required to assure itself that nuclear power plants were complying with regulatory and licensing requirements.

1.22 We found that the CNSC included in its annual inspection plans for the 2013–14 and 2014–15 fiscal years only about 48 percent of the inspections scheduled in its five-year plan for those years. We were unable to determine the precise percentage because there were discrepancies between different planning documents. The decisions about which inspections the CNSC would and would not carry out from the five-year plan were based on professional judgment, and the rationales for those decisions—such as on how risks were taken into account—were not documented. Because the rationales were not documented, we could not determine the significance of the inspections that were not carried out.

1.23 According to the CNSC’s records, work was under way in 2013 to develop a consistent process for reviewing and updating the five-year plan, including guidance criteria to help determine how an inspection gets added to or removed from the plan, or how its frequency gets adjusted. This work was to be completed by January 2016. We found that as of April 2016, little progress had been made. Senior CNSC management told us that this lack of progress was due to staff having to work on other regulatory activities.

1.24 The preparation of annual site inspection plans. The CNSC also prepares annual inspection plans that set out the inspections it plans to carry out at each nuclear power plant during the upcoming fiscal year. During the annual inspection planning process, which includes internal consultations, CNSC management decides which inspections from the five-year inspection plan scheduled for the upcoming year will be included in the annual plans.

1.25 According to the CNSC’s process, additional site inspections are then added to the annual site inspection plan based on considerations such as previous compliance activities, major changes to licensee programs or operations, major events, and availability of CNSC staff. For example, one such inspection was conducted to oversee the licensee’s operation of reactors after they had been refurbished. However, much of this planning process, including the rationale for decisions about what inspections were planned, was based on professional judgment and not documented.

1.26 Supplemental inspections—those that are not contained in the initial annual plans—are inspections that the CNSC may decide to conduct during the year. For example, these may respond to additional emerging issues. One such inspection was conducted to examine a possible issue with nuclear fuel quality. For the 2013–14 and 2014–15 fiscal years, 15 percent (33 out of 226) of site inspections completed were supplemental inspections (Exhibit 1.4).

Exhibit 1.4—Some site inspections were not completed as planned

| Site inspections that were completed or not completed as planned | Fiscal year | Totals | |

|---|---|---|---|

| 2013–14 | 2014–15 | ||

| Number of planned inspections listed in annual plans | 138 | 117 | 255 |

| Less: Inspections not completed that were listed in the annual plans | -24 | -38 | -62 |

| Subtotal: Number of inspections completed that were listed in the annual plans | 114 | 79 | 193 |

| Add: Supplemental inspections added to plan during year and completed | +12 | +21 | +33 |

| Total number of inspections completed | 126 | 100 | 226 |

Source: Based on information provided by the Canadian Nuclear Safety Commission

1.27 We found that the guidance for developing annual site inspection plans did not contain the methodology and criteria needed to prioritize site inspections to help staff develop annual site inspection plans consistently and reliably. Also, the CNSC did not document its planning to show that it systematically took risk factors into account. Therefore, the CNSC could not demonstrate that the annual site inspection plans set out the appropriate number and types of inspections that were needed to verify that nuclear power plants were complying with regulatory and licensing requirements.

1.28 The CNSC’s ability to carry out its annual site inspection plans. The CNSC’s annual site inspection plans for the 2013–14 and 2014–15 fiscal years show that 255 site inspections were to be carried out (Exhibit 1.4). Based on inspection planning schedules and additional documentation and data provided by CNSC, 76 percent (193 out of 255) of its planned site inspections were completed. It was difficult for us to determine these figures, because the CNSC’s planning records contained inaccuracies and were incomplete. For example, there were planned inspections that were recorded as completed when they were not, and others that were not shown as completed but were completed.

1.29 We found that site inspections planned for the 2013–14 and 2014–15 fiscal years were not done in the year planned for various reasons, such as inspectors and technical specialists not being available, lack of inspection guides needed to conduct the inspections, or because of the licensee’s operations and outage schedule. For example, some inspections can be completed only when a reactor is shut down. If the licensee reschedules a planned shutdown, the inspection needs to be rescheduled as well. The CNSC also informed us that other planned inspections were not done in the year planned because CNSC officials decided that they were no longer necessary.

1.30 CNSC officials informed us that when an inspection is not completed as planned, it may be rescheduled and completed in a future year. For example, out of the 24 inspections that were included in the plans for the 2013–14 fiscal year but were not completed, 8 were rescheduled and completed during the following fiscal year. We were told that another 4 were also rescheduled to the 2014–15 fiscal year but were not completed.

1.31 The determination of staffing requirements. In view of our findings about planning for and carrying out site inspections, the CNSC could not show that it had assigned the appropriate number of staff commensurate with risk. The CNSC has yet to determine the minimum number of inspections required, in order to determine the number of staff at the levels needed.

1.32 We found that the CNSC had not done an assessment that included rationales for the staffing required to carry out inspections at nuclear power plants. However, several factors pointed to a risk that the CNSC may not be appropriately staffed to conduct site inspections:

- Staffing-related issues were among the reasons why not all inspections the CNSC had planned for the 2013–14 and 2014–15 fiscal years were carried out.

- While senior management told us that they believed there were enough inspectors and that more were reassigned as issues arose, we were told by site inspectors and site supervisors at every nuclear power plant that there were either not enough inspectors at their sites or not enough at the levels needed.

- Officials pointed out to us that a number of staffing and job-related changes had affected the work of inspectors. For example, the CNSC decided that only inspectors could lead inspections, whereas before, inspections could also be led by other technical staff. The CNSC has also been hiring a number of junior staff to renew its workforce as senior staff retire.

1.33 Recommendation. The Canadian Nuclear Safety Commission should develop and implement a well-documented planning process for site inspections of nuclear power plants that can demonstrate that the process is systematic and risk-informed. This should include determining the minimum required frequency and type of inspections needed to verify compliance, updating the five-year baseline inspection plan, and assessing whether it is assigning the appropriate number and levels of staff to carry out the number of inspections required to verify compliance.

The Canadian Nuclear Safety Commission’s response. Agreed. The Canadian Nuclear Safety Commission (CNSC) has instituted plans to systematically update its five-year baseline inspection plan in a risk-informed manner to include a review of staff allocation, the frequency, and the type of inspections needed to verify compliance. The CNSC will target completion by 31 March 2017. On an annual basis, the CNSC already applies risk-informed decision making to prioritize areas to be inspected and to determine the number of site inspections and the level of resources required to conduct these activities, taking into account professional judgment and historical safety track records for each plant. The CNSC agrees that, through better documentation, it could demonstrate that the planning process is adequate and achieve greater consistency in the conduct of site inspections at nuclear power plants.

The effectiveness of the CNSC’s comprehensive compliance oversight program is demonstrated by the industry’s annual safety performance ratings and affirmed through international benchmarking and independent peer reviews. Each year, the CNSC publishes the safety ratings on its website in a regulatory oversight report on the safety performance of each of Canada’s nuclear power plants. The CNSC has allocated more than 200 staff to the licensing and compliance oversight of nuclear power plants, including 24 on-site inspectors and numerous technical experts. A recent internal audit of the overall CNSC operations planning process (2016) concluded that there is reasonable assurance that the management control framework is adequate and functioning appropriately, adequate tools and guidance are in place, and the results are implemented and documented.

1.34 Criteria for initiating program-based inspections. Broad, program-based, audit-like inspections, known as Type I inspections, are a tool the CNSC uses to confirm whether the programs carried out by nuclear power plants are effective and compliant (Exhibit 1.5). The CNSC did not conduct any Type I inspections during the period covered by our audit. The CNSC’s documents show that in 2013, management identified the need to develop detailed criteria to show when to initiate this type of inspection. We found that as of January 2016, the CNSC had still not developed these criteria.

Exhibit 1.5—There are two types of nuclear power plant inspections

| Inspection Type | Description |

|---|---|

|

Type I |

Examples of what a Type I inspection may look at:

|

|

Type II |

Examples of what a Type II inspection may look at:

|

Source: Based on information provided by the Canadian Nuclear Safety Commission

1.35 Recommendation. The Canadian Nuclear Safety Commission should develop detailed criteria to help it identify when to conduct Type I inspections.

The Canadian Nuclear Safety Commission’s response. Agreed. Criteria for determining when Type I site inspections are to be conducted are currently being formalized and the Canadian Nuclear Safety Commission will include them in its management system by December 2016.

During the audit period, several major relicensing or refurbishment activities for nuclear power plants entailed comprehensive compliance reviews (including desktop reviews, site inspections, and reviews of unplanned events). These reviews provided the required information needed to ensure regulatory compliance, and as a result Type I inspections were not required during that period.

Conducting inspections

The Canadian Nuclear Safety Commission did not always follow its own inspection procedures

1.36 Overall, we found that the Canadian Nuclear Safety Commission (CNSC) could not show that inspectors always followed CNSC procedures when carrying out and documenting inspections of nuclear power plants. This has led to inconsistencies, gaps in documentation, and missed opportunities for identifying improvements in conducting inspections. For example, although the CNSC requires that inspection guides be developed and approved before inspections take place, we found that this was done for only one quarter of inspections during the 2013–14 and 2014–15 fiscal years. We also found that the CNSC did not provide clear guidance to its inspectors about which information they should retain in inspection files once the final inspection reports were complete. Because some information was not retained, the CNSC could not show that inspection reports fully and accurately reflected observations made during inspections. The CNSC also rarely used the information gathered during inspections to conduct lessons-learned exercises that could identify ways to improve its site inspections.

1.37 These findings are important because following procedures ensures that all inspections are carried out in a way that verifies compliance with the applicable regulatory and licence requirements and that noted deficiencies and lessons learned are captured, documented, and addressed in a consistent way.

1.38 Our analysis supporting this finding presents what we examined and discusses

- establishing and using assessment criteria for individual inspections,

- documenting inspections and retaining records, and

- conducting lessons-learned exercises.

1.39 The CNSC’s nuclear power plant inspection procedures require that the inspection team prepare a plan for each inspection beforehand, setting out the key steps it will follow, including the use of an approved inspection guide tailored for the subject being examined. This is supposed to draw on the compliance verification criteria, as set out in licence condition handbooks that the CNSC issued to each nuclear power plant. The nuclear power plant is to be assessed against those criteria to ensure that applicable regulatory and licence requirements are verified for compliance. For example, one inspection criterion could require the inspector to verify whether there is an approved permit to manage combustible material, including waste.

1.40 According to the procedures, inspectors are to document their observations in the guide as they conduct the inspections. They may also prepare supplementary checklists and worksheets, such as forms used to record data, lists of questions to ask, and inspection routes to follow while conducting the inspections. This helps ensure that the inspection assesses the nuclear power plant against the applicable criteria and provides a record to be used in drafting the inspection report. Other types of documentation used, such as email correspondence, presentations to licensees, and documents prepared by the licensee, may also be included in an inspection. After an inspection is completed, an inspection report is prepared and sent to the licensee.

1.41 Our recommendations in this area of examination appear at paragraphs 1.48 and 1.50.

1.42 What we examined. We examined the practices and procedures the CNSC used to conduct inspections of nuclear power plants. We did not do a technical assessment of the CNSC’s inspection methods and procedures.

1.43 Establishing and using assessment criteria for individual inspections. We tested whether the CNSC followed its procedures that require inspection guides containing assessment criteria to be prepared for each inspection. To do so, we analyzed a database that the CNSC used to track the development and approval of inspection guides that contained the criteria. This database showed that only 25 percent (56) of the 226 site inspections the CNSC carried out under its plans for the 2013–14 and 2014–15 fiscal years had approved guides. About 31 percent (71 out of 226) had draft or pilot inspection guides and 27 percent (61 out of 226) had no guide. For about 17 percent (38 out of 226) of the inspections, the database was missing data and did not indicate whether there was a guide. The CNSC’s procedures stipulate that an inspection is not to be conducted without an approved guide.

1.44 Where there were no inspection guides or the guides were in draft or pilot format, inspectors told us that they used their professional judgment to conduct the inspection. We recognize that flexibility may be required on a case-by case basis. However, without the use of guides containing inspection criteria, the CNSC cannot be sure, nor can it demonstrate, that it is conducting inspections that use appropriate criteria to assess compliance with regulatory and licence requirements.

1.45 Documenting inspections and retaining records. The CNSC’s procedures require that during inspections, inspectors record their observations in the inspection guide against each criterion used to assess whether the plants are complying with regulatory and licence requirements. Inspectors may also use supplementary checklists, worksheets, and other supporting documents. We used representative sampling to examine 42 CNSC inspections of nuclear power plants to assess what documentation was retained for each inspection. Except for the final inspection report, we found that the documentation prepared during the inspections was not consistently retained and that, overall, there were few documents, such as completed guides, checklists, and other worksheets. We also found that, due to the lack of documentation, the CNSC was unable to demonstrate that everything that was supposed to be checked during its inspections had been examined, and that the observations that inspectors had made during inspections were accurately reflected in the final inspection reports.

Transitory records—Records that are required only for a limited time to ensure the completion of a routine action or the preparation of a subsequent record. Transitory records do not include records required by government institutions or Ministers to control, support, or document the delivery of programs, to carry out operations, to make decisions, or to account for activities of government.

Source: Authority for the Destruction of Transitory Records, Section 4, Library and Archives Canada

1.46 In July 2014, senior CNSC officials decided that preliminary and transitory inspection notes should be destroyed after the final inspection report had been issued to the licensee. Such documentation may be destroyed under the Library and Archives of Canada Act when the material meets the definition of transitory records.

1.47 Although CNSC inspectors were told about this decision, the CNSC’s inspection procedures, which outline how to conduct an inspection, were not revised to reflect this decision, and they did not specify exactly what should be destroyed and what should be kept as part of the inspection file.

1.48 Recommendation. The Canadian Nuclear Safety Commission should ensure that its inspections follow its own procedures. This requires that it develop approved inspection guides with appropriate criteria before conducting inspections to assess that nuclear power plants are complying with applicable regulatory and licence requirements. The Canadian Nuclear Safety Commission should also clearly explain to its staff how to decide which documents should be considered transitory and which documents should be retained after they issue inspection reports.

The Canadian Nuclear Safety Commission’s response. Agreed. The Canadian Nuclear Safety Commission (CNSC) has taken immediate action to raise awareness and ensure observance of site inspection procedures by site inspectors. The CNSC commits to completing by December 2016 a procedure document that will specify management expectations regarding the conduct of site inspections, including the consistent use of authorized inspection guides. The CNSC will also provide clear document retention instructions to site inspectors.

The CNSC has a comprehensive management system which contains processes and procedures that cover all steps in the compliance process, including inspection guides for use during site inspections. Through its compliance verification activities, the CNSC ensures that licensees conform to the Nuclear Safety and Control Act, its regulations, and all applicable regulatory documents, as well as site-specific licence conditions handbooks that set out detailed compliance verification criteria. The conversion of these criteria into detailed field inspection guides against which an inspector conducts an inspection will ensure more consistency.

1.49 Conducting lessons-learned exercises. According to the CNSC’s procedure manuals for conducting inspections of nuclear power plants, lessons learned help identify improvements in conducting inspections and are to be discussed and documented after completing each inspection. We used representative sampling to review 42 of CNSC’s site inspections of nuclear power plants and found that lessons learned were documented for only two inspections. We also interviewed the CNSC’s staff responsible for carrying out site inspections and were told that lessons-learned exercises were rarely conducted.

1.50 Recommendation. The Canadian Nuclear Safety Commission should ensure that it documents lessons learned in carrying out its inspections, to help it make continuous improvements to its inspection practices.

The Canadian Nuclear Safety Commission’s response. Agreed. The Canadian Nuclear Safety Commission (CNSC) will improve staff awareness of, and adherence to, current procedural requirements to capture the lessons learned from inspections. In addition, new processes will be established by December 2016 to track the implementation of these lessons for continuous improvement of regulatory oversight.

The CNSC’s nuclear power plant inspection teams have effective practices for capturing and sharing lessons learned from site and other inspections, such as weekly staff meetings and quarterly full-team meetings (site staff, specialists, and project officers). In addition, a database to capture and share operational regulatory oversight experience for nuclear power plants, and a new consolidated site-specific regulatory status report (in pilot stage) for nuclear power plants, are now available to record lessons learned. The CNSC will ensure that these practices are consistently applied.

Enforcing compliance with regulatory and licence requirements

The Canadian Nuclear Safety Commission followed up to confirm that nuclear power plants corrected compliance violations it identified, but did not always issue final reports on time

1.51 Overall, we found that the Canadian Nuclear Safety Commission (CNSC) followed up on instances of non-compliance identified through site inspections and confirmed that the nuclear power plants involved had taken corrective action or were in the process of doing so. We also found that the CNSC was slow to issue final inspection reports to nuclear power plant operators in about one third of cases.

1.52 This is important because, through timely enforcement activities, the CNSC ensures that nuclear power plants address the safety and control issues noted during an inspection and documented in the final inspection report. Even though the CNSC is to immediately inform the operator when it identifies a compliance issue during a site inspection so that safety concerns can be immediately addressed, it is important that the CNSC issue its reports to plant operators on time, because the 60-day period the operators have to provide a response to the CNSC only starts after they receive the final inspection report.

1.53 Our analysis supporting this finding presents what we examined and discusses

1.54 Immediately following a site inspection, the CNSC’s inspection staff are to meet with the nuclear power plant staff members and inform them of the preliminary findings, including any compliance issues. This is to be followed by a final inspection report sent to the licensee. When an inspection concludes that a licensee is not complying with applicable regulatory or licence requirements, the CNSC must carry out enforcement actions to encourage the licensee to correct the issue, such as issuing an action notice. This requires the licensee to respond and show how long it will take them to correct the issue.

1.55 The licensee must respond to the CNSC with an action plan within 60 days and its intended timeline to address the non-compliance. This action plan is to be reviewed by the CNSC’s staff, including its technical specialists. Depending on the type of non-compliance, a licensee may require varying amounts of time to address the issues. For example, the licensee may have to install new equipment, or revise training material for its staff. The CNSC’s inspectors must then ensure that the licensee has carried out the required changes.

1.56 Our recommendation in this area of examination appears at paragraph 1.61.

1.57 What we examined. We examined whether the CNSC followed up to confirm that nuclear power plants corrected non-compliance identified during its inspections and issued its inspection reports to licensees on time.

1.58 Enforcement. We used representative sampling to select 42 site inspections. Within our sample, 26 inspections reported non-compliance, which required nuclear power plants to take corrective action. For example, one inspection report asked a nuclear power plant to develop and carry out a corrective action plan to ensure that its radiation environmental monitoring processes and procedures were current. We found that the CNSC followed up on all of these cases and confirmed that the nuclear power plants had taken or were in the process of taking corrective action. The CNSC’s procedures also showed that, when further inspections were done, inspectors were to verify that corrective actions had indeed been taken.

1.59 We also noted that, for our sample of 42 inspections, the CNSC made 94 recommendations to licensees. For example, following an inspection of the maintenance planning and scheduling at one nuclear power plant, the CNSC recommended that the licensee formally review action items at the end of its maintenance meetings. The purpose of recommendations is to improve performance based on good practice in areas outside of regulatory requirements. As such, the licensees are not obliged to accept the recommendations.

1.60 Time taken to issue inspection reports. The CNSC’s standard time for issuing inspection reports to nuclear power plants is 50 business days after completing on-site inspection activities, including meeting with the licensee’s officials to discuss findings. The CNSC’s target was to meet this standard 80 percent of the time. According to data provided by the CNSC, during the period of our audit, this standard was met only 64 percent of the time.

1.61 Recommendation. The Canadian Nuclear Safety Commission should determine why it does not issue timely final inspection reports and decide whether it needs to make any changes to its processes or standards.

The Canadian Nuclear Safety Commission’s response. Agreed. Action completed. Several corrective actions were identified and implemented, with the result that in the 2015–16 fiscal year, the service standard for delivery of final inspection reports was consistently met. The Canadian Nuclear Safety Commission will continue to monitor observance of its service standard.

Conclusion

1.62 Site inspections are one of the key tools that the Canadian Nuclear Safety Commission (CNSC) uses to oversee the operation of nuclear power plants to verify that the environment and the health, safety, and security of Canadians are protected. We concluded that the CNSC could not show that it had adequately managed its site inspections of nuclear power plants. The CNSC could not demonstrate that its inspection plans included the appropriate number and types of inspections and that it had the staff needed to verify that nuclear power plants were complying with all applicable requirements or that site inspections were carried out according to the CNSC’s procedures.

About the Audit

The Office of the Auditor General’s responsibility was to conduct an independent examination of the Canadian Nuclear Safety Commission’s management of its site inspections of nuclear power plants, to provide objective information, advice, and assurance to assist Parliament in its scrutiny of the government’s management of resources and programs.

All of the audit work in this report was conducted in accordance with the standards for assurance engagements set out by the Chartered Professional Accountants of Canada (CPA) in the CPA Canada Handbook—Assurance. While the Office adopts these standards as the minimum requirement for our audits, we also draw upon the standards and practices of other disciplines.

As part of our regular audit process, we obtained management’s confirmation that the findings in this report are factually based.

Objective

The objective of the audit was to determine whether the Canadian Nuclear Safety Commission (CNSC) had adequately managed its site inspections of nuclear power plants to verify that the environment and the health, safety, and security of Canadians were protected.

Scope and approach

The audit focused on the CNSC’s site inspection activities for Canada’s four operating nuclear power plants and one nuclear power plant in Quebec that had been shut down in December 2012. We interviewed senior managers and key staff at the CNSC’s headquarters in Ottawa responsible for nuclear power plant regulatory activities. We included compliance and licensing staff responsible for site offices at nuclear power plants. We also interviewed senior managers responsible for key supporting functions such as human resources and information technology. We interviewed CNSC staff at all four operating nuclear power plants. We also visited three nuclear power plants, where we met with CNSC staff responsible for compliance activities and observed how the CNSC carried out its inspections.

During the audit, we reviewed documentation on how inspections at nuclear power plants were planned and conducted, as well as how enforcement activities were carried out. We also obtained explanations from management about the information we received. For certain audit tests, we used representative sampling to base our results. Where representative sampling was used, sample sizes were sufficient to report on the sampled population with a confidence of 90 percent and a margin of error of +10 percent.

While this was an audit of the CNSC, we did not do a technical assessment of the CNSC’s inspection methods and procedures, nor did we audit the records of nuclear power plant operators.

Criteria

To determine whether the Canadian Nuclear Safety Commission (CNSC) had adequately managed its site inspections of nuclear power plants to verify that the environment and the health, safety, and security of Canadians were protected, we used the following criteria:

| Criteria | Sources |

|---|---|

|

The CNSC assesses whether it has the appropriate number of qualified people in the right place at the right time to conduct site inspections and enforcement activities at nuclear power plants. |

|

|

The CNSC establishes and implements a systematic and risk-based approach for planning and prioritizing site inspections at nuclear power plants. |

|

|

The CNSC conducts site inspections and enforcement activities at nuclear power plants that are consistent with established plans and priorities and with its own procedures. |

|

Management reviewed and accepted the suitability of the criteria used in the audit.

Period covered by the audit

The audit covered the period during the 2013–14 and 2014–15 fiscal years. Audit work for this report was completed on 28 July 2016.

Audit team

Principal: John Affleck

Directors: Mathieu Lefèvre, Daniel Thompson

Tanya Burger

Janice Carkner

Jeff Graham

Nicole Hutchinson

Maxine Leduc

List of Recommendations

The following is a list of recommendations found in this report. The number in front of the recommendation indicates the paragraph where it appears in the report. The numbers in parentheses indicate the paragraphs where the topic is discussed.

Planning inspections

| Recommendation | Response |

|---|---|

|

1.33 The Canadian Nuclear Safety Commission should develop and implement a well-documented planning process for site inspections of nuclear power plants that can demonstrate that the process is systematic and risk-informed. This should include determining the minimum required frequency and type of inspections needed to verify compliance, updating the five-year baseline inspection plan, and assessing whether it is assigning the appropriate number and levels of staff to carry out the number of inspections required to verify compliance. (1.21–1.32) |

The Canadian Nuclear Safety Commission’s response. Agreed. The Canadian Nuclear Safety Commission (CNSC) has instituted plans to systematically update its five-year baseline inspection plan in a risk-informed manner to include a review of staff allocation, the frequency, and the type of inspections needed to verify compliance. The CNSC will target completion by 31 March 2017. On an annual basis, the CNSC already applies risk-informed decision making to prioritize areas to be inspected and to determine the number of site inspections and the level of resources required to conduct these activities, taking into account professional judgment and historical safety track records for each plant. The CNSC agrees that, through better documentation, it could demonstrate that the planning process is adequate and achieve greater consistency in the conduct of site inspections at nuclear power plants. The effectiveness of the CNSC’s comprehensive compliance oversight program is demonstrated by the industry’s annual safety performance ratings and affirmed through international benchmarking and independent peer reviews. Each year, the CNSC publishes the safety ratings on its website in a regulatory oversight report on the safety performance of each of Canada’s nuclear power plants. The CNSC has allocated more than 200 staff to the licensing and compliance oversight of nuclear power plants, including 24 on-site inspectors and numerous technical experts. A recent internal audit of the overall CNSC operations planning process (2016) concluded that there is reasonable assurance that the management control framework is adequate and functioning appropriately, adequate tools and guidance are in place, and the results are implemented and documented. |

|

1.35 The Canadian Nuclear Safety Commission should develop detailed criteria to help it identify when to conduct Type I inspections. (1.34) |

The Canadian Nuclear Safety Commission’s response. Agreed. Criteria for determining when Type I site inspections are to be conducted are currently being formalized and the Canadian Nuclear Safety Commission will include them in its management system by December 2016. During the audit period, several major relicensing or refurbishment activities for nuclear power plants entailed comprehensive compliance reviews (including desktop reviews, site inspections, and reviews of unplanned events). These reviews provided the required information needed to ensure regulatory compliance, and as a result Type I inspections were not required during that period. |

Conducting inspections

| Recommendation | Response |

|---|---|

|

1.48 The Canadian Nuclear Safety Commission should ensure that its inspections follow its own procedures. This requires that it develop approved inspection guides with appropriate criteria before conducting inspections to assess that nuclear power plants are complying with applicable regulatory and licence requirements. The Canadian Nuclear Safety Commission should also clearly explain to its staff how to decide which documents should be considered transitory and which documents should be retained after they issue inspection reports. (1.43–1.47) |

The Canadian Nuclear Safety Commission’s response. Agreed. The Canadian Nuclear Safety Commission (CNSC) has taken immediate action to raise awareness and ensure observance of site inspection procedures by site inspectors. The CNSC commits to completing by December 2016 a procedure document that will specify management expectations regarding the conduct of site inspections, including the consistent use of authorized inspection guides. The CNSC will also provide clear document retention instructions to site inspectors. The CNSC has a comprehensive management system which contains processes and procedures that cover all steps in the compliance process, including inspection guides for use during site inspections. Through its compliance verification activities, the CNSC ensures that licensees conform to the Nuclear Safety and Control Act, its regulations, and all applicable regulatory documents, as well as site-specific licence conditions handbooks that set out detailed compliance verification criteria. The conversion of these criteria into detailed field inspection guides against which an inspector conducts an inspection will ensure more consistency. |

|

1.50 The Canadian Nuclear Safety Commission should ensure that it documents lessons learned in carrying out its inspections, to help it make continuous improvements to its inspection practices. (1.49) |

The Canadian Nuclear Safety Commission’s response. Agreed. The Canadian Nuclear Safety Commission (CNSC) will improve staff awareness of, and adherence to, current procedural requirements to capture the lessons learned from inspections. In addition, new processes will be established by December 2016 to track the implementation of these lessons for continuous improvement of regulatory oversight. The CNSC’s nuclear power plant inspection teams have effective practices for capturing and sharing lessons learned from site and other inspections, such as weekly staff meetings and quarterly full-team meetings (site staff, specialists, and project officers). In addition, a database to capture and share operational regulatory oversight experience for nuclear power plants, and a new consolidated site-specific regulatory status report (in pilot stage) for nuclear power plants, are now available to record lessons learned. The CNSC will ensure that these practices are consistently applied. |

Enforcing compliance with regulatory and licence requirements

| Recommendation | Response |

|---|---|

|

1.61 The Canadian Nuclear Safety Commission should determine why it does not issue timely final inspection reports and decide whether it needs to make any changes to its processes or standards. (1.60) |

The Canadian Nuclear Safety Commission’s response. Agreed. Action completed. Several corrective actions were identified and implemented, with the result that in the 2015–16 fiscal year, the service standard for delivery of final inspection reports was consistently met. The Canadian Nuclear Safety Commission will continue to monitor observance of its service standard. |